Always stay up to date

Innovative mobility, exciting trends for the future and high RPMs: Subscribe now to get notified of new content.

Subscription successful.

Subscription failed. If you need help follow the link for support.

Parked in a heavily cordoned-off area near Munich is a brown BMW X5 Protection VR6. The vehicle already shows numerous pockmarks: bullet holes in the sheet metal, cracks in the windows. The warning shout “Attention!” echoes across the space, followed by a whistle. Then three gun shots ring though the air. Glass fragments fly. A shell casing clatters on the concrete floor. A cloud of dust rises from the windshield of the armored car. As it drifts away, the all-clear is given.

Daniel Huber takes off his ear protectors, steps out of the steel-clad shelter and walks up to the armored vehicle. An employee of the ballistics test center in Munich is already searching the inside of the car for projectile remains and fragments. Then he inspects a piece of film he placed behind the windshield.

“This film has the same resistance as human skin,” explains Daniel Huber. If it had been damaged by fragments or parts of the projectile, the occupants of the armored vehicle would have been at risk of injury or even death. The film is intact. “Passed,” says Daniel Huber, satisfied. The test center employee puts three green stickers on the bullet holes – a sign that the armored BMW X5 has passed this test as well.

Daniel Huber is BMW’s engineer for armored vehicles and bulletproof vehicles. Born in Munich, he is responsible for the complete protection of the passenger cabin – and therefore the safety and lives of those inside.

“In addition to the normal dangers of road traffic, customers who buy an armored car are exposed to special threats, such as attacks with firearms and explosives,” says Huber. “Protecting our customers from these dangers is both the challenge of my job and the motivation behind it.”

After graduating from high school, Huber debated whether to join the police force or to study. In the end he opted for the latter, enrolling in a mechanical engineering course at the TU Munich. He wrote his thesis at BMW on the subject of security and emergency vehicles. “This is how I learned about this exciting department at the company I’d always wanted to work for,” the 35-year-old explains. “After graduating from the University of the Federal Armed Forces in Hamburg, I was able to combine my interests in mechanical engineering and security here.”

Customers who buy an armored car are exposed to special threats, such as attacks with firearms and explosives.

Engineer for BMW armored vehicles

BMW’s new armored car

Daniel Huber has been working at BMW since 2011. His latest product is the BMW X5 Protection VR6. “Vehicle Resistance 6” is its ballistic protection rating (the maximum level is VR10). For BMW, this is tested by the Ballistics Testing Office in Munich, a department of the Bavarian Calibration Office, and, if successful, awarded a certificate recognized worldwide. A bulletproof vehicle with a VR6 ballistic protection rating must be able to withstand fire from an AK-47 assault rifle (also known as a Kalashnikov). In addition, armored vehicles by BMW provide protection from explosives.

For Huber, the certification by the ballistics test center and the final explosives test are the most exciting yet tense part of the development of a BMW armored vehicle. “If a projectile or fragment enters the vehicle during firing, we call this penetration,” he explains. If this happens, the armored car he has developed will fail the official certification.

Huber observes the test center shooter intently as he sets up his rifle. Iron-core ammunition, 7.62 x 39 mm caliber. The auditors focus above all on the supposed weak points of the armored car: seams between the armored components such as window joints and door frames.

This time, three projectiles strike the car around the door lock. These are the last of a total of 306 shots. The official inspects the interior and the film again, neither of which show any signs of penetration. The BMW X5 Protection VR6 has passed the official ballistics certification. But Huber is not ready to celebrate just yet. The explosives certification is due to take place next week.

Bulletproof glass meets ballistics: testing materials on the shooting range

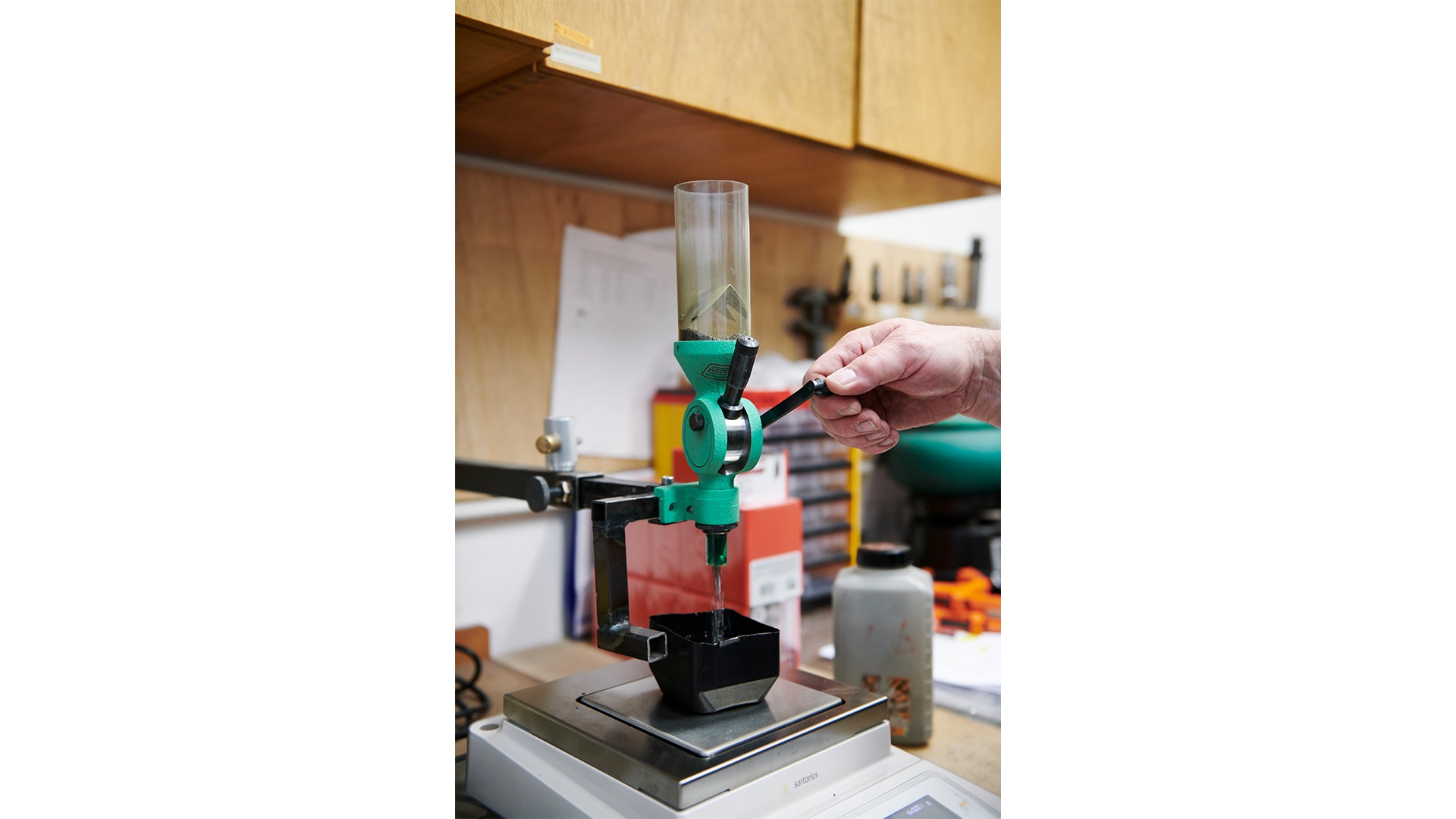

Daniel Huber begins testing the materials used to protect the passenger compartment long before the vehicles are fired at. “Many suppliers have their steel or ballistic glass officially certified,” he explains. “At BMW, however, we are committed to having all materials for armored vehicles retested and certified ourselves.” This is done on the shooting range at the ballistics test center in Munich. There Huber regularly arranges for plates of armored steel, safety glass or synthetic fiber such as aramid to be shot at. Here, too, the decisive factor is penetration.

The tests on the shooting range tend to speak for themselves, says Huber, remembering with a grin one manufacturer who gave him a supposedly bulletproof space flight material. “When we fired at it just a medium caliber rifle, the $20,000 test piece shattered into a thousand pieces.”

He also describes the “constant stream of innovations” when it comes to materials. When a new steel alloy becomes even just one millimeter thinner while providing the same protection, this translates into 18 pounds less weight per square meter. Besides safety, weight reduction is the most important goal in Daniel Huber’s development work. Bulletproof vehicles should be as light as possible, not least to allow them to exit dangerous situations quickly. The BMW Driving Experience also offers special driver training courses for such maneuvers.

One supplier offered us a supposedly bulletproof space flight material. But during the ballistics test, the $20,000 plate shattered into a thousand pieces.

Engineer for BMW armored vehicles

- What is the name of BMW’s new armored SUV?

It’s called the BMW X5 Protection VR6, successor to the BMW X5 Security and BMW X5 Security Plus. It was unveiled at the IAA 2019. How much does a bulletproof BMW weigh?

The additional weight depends on how much of the car is armored and what equipment is included. The armor for the VR6 class weighs around 1,760 pounds.Do armored vehicles have a special engine?

No. BMW’s bulletproof vehicles are equipped with the most powerful production engines for their class. The BMW X5 Protection VR6 has the 530 hp engine from the BMW X5 M50i.Where are BMW armored vehicles built?

The base vehicle for the BMW X5 Protection VR6 is built at the BMW factory in Spartanburg (➜ Visit South Carolina), while the retrofitting for the armored vehicle is done at the BMW factory in Mexico.- How much does a BMW bulletproof vehicle cost?

There are no general prices for these cars. All prices are available upon request.

The basic security concept: inconspicuous and light

The chassis and the electronics such as DSC stability controls are adapted to the greater weight of BMW’s armored vehicles, as are the relevant parts. This includes stronger motors to roll the heavy bulletproof glass windows up and down. According to Huber, the driving experience is also different. What is especially impressive is that “because of the protective panels, there is virtually no outside noise or noise from the engine audible. This makes the engine sound much deeper than in a standard vehicle.”

Another key aim in developing armored cars is inconspicuousness. “Passengers should not notice that they’re riding in an armored vehicle, but rather enjoy the same comfort as in a standard vehicle,” says Huber. Most customers also want the exterior to be as discreet as possible – such as embassy employees in dangerous regions and countries. “The less noticeable an armored vehicle is, the less likely it is to be targeted,” explains Huber. This seems to be a successful strategy. BMW has been making bulletproof cars for 40 years, and Huber is only aware of a few actual attacks.

New threat scenarios require new security concepts

Daniel Huber’s customers are primarily security agencies from around the world. The armored BMW X5 is often used as a tactical escort vehicle for personal protection or if the terrain is not suitable for an armored limousine. Huber is in regular contact with his customers, for example about new threat situations. Drone attacks with explosive devices are one such case, having increased in recent years. For this reason, the BMW X5 Protection VR6 has an optional special protective roof.

Shooting at and blowing up cars – it sounds like the dream job for a gun lover or a pyromaniac. But Huber is neither. What interests him is working on a car from start to finish. “When you’re developing standard cars, you have a clearly defined area that you’re responsible for, which is often just one piece of the car. I, on the other hand, am responsible for the entire vehicle: from front to back, from bottom to top – and from the initial idea to the final test.”

What are armored vehicles?

Armored vehicles are passenger cars or commercial vehicles with special armor to protect the passengers or cargo from outside attacks with firearms or explosives. The materials used are armored steel, ballistic glass and synthetic fibers such as aramid.

The final test for BMW’s armored vehicles: the equivalent of 33 pounds of TNT

Last but not least, every BMW armored vehicle has to prove itself in so-called blast tests. This involves exploding various hand grenades above, below and, finally, to the sides of the vehicle. 13 feet away from the car, the equivalent of 33 pounds of TNT are set off. Inside the armored car are dummies with pressure sensors that measure the impact the explosions have on the human body.

The explosion tests for the BMW X5 Protection VR6 take place a few days after the ballistics certification. But not even our team from BMW.com are allowed to watch. With all due discretion, Huber tells us why: the customer is present and does not want reporters or photographers on site. Huber’s job is definitely not a run-of-the-mill engineering job.

One thing we can tell you: The BMW X5 Protection VR6 passed the explosion tests as well.

“Pay attention, 007” – the list of equipment of armored vehicles is a little reminiscent of a Bond film. The BMW X5 Protection VR6 comes with:

Safety glass that is up to 30 millimeters thick and armored steel that is over four millimeters thick on all sides of the passenger cabin.

In an attack, the vehicle locks the doors and windows, accompanied by a visual and audio signal.

An intercom system allows passengers to maintain contact with the outside world without having to open the doors or windows.

Tires specifically made for emergencies make it possible to continue driving at a speed of up to 50 mph even after losing pressure.

- Emergency lights on the radiator grill and as an attachment for the roof.

Photos: Andre Kirsch; Author: Ingo Wilhelm; Video: Monacoframe