Our tool for managing your consent to our use of cookies is temporarily offline.

For this reason, some functions that require your consent to the use of cookies may not be available.

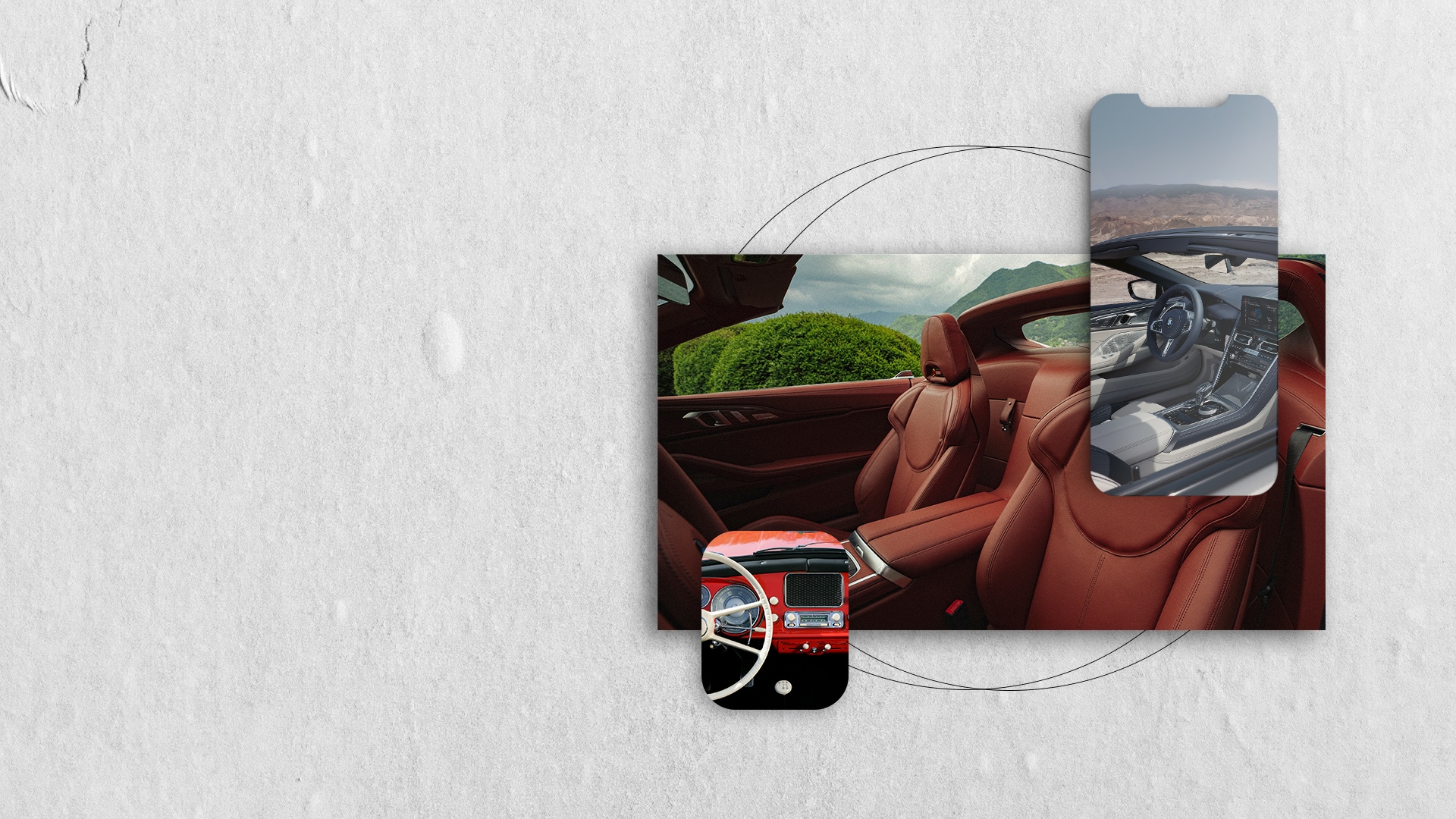

BMW EXPLAINED

The BMW Podcast: Changing Lanes

Changing Lanes is the official podcast from BMW. In these audio series, we take you with us on new journeys through the BMW universe. Find out more about sustainability, innovation, technology, mobility and the latest trends. You can find and subscribe to Changing Lanes on all major podcast platforms, so tune in!

Listen now